-

PTFE Micropore Filter Cartridge (hydrophobicity)

IntroductionThe filtration media of PTFE micropore filter cartridge is hydrophobicity PTFE membrane. It is constructed of two materials PTFE and PP to meet high standards of chemical and pharmaceutical industry. The benefit summary: strong hydrophobicity, high retention rate, super chemical tolerance and thermal stability, good intension, withstand shocks and back pressures. All products have passed 100% integrity testing. The biological safety and endotoxin guideposts are in accord with FDA and Chinese Pharmacopoeia. Specifications and technical parametersFilter medium: hydrophobicity PTFE membrane

Support layer: PP

Filter cage: PP

Pore size: 0.05、0.1、0.2、0.45、1 (μm)

Length: 5"、10"、20"、30"、40"

Sealing material: Silastic, NBR, EPDM, Viton

Airtight method: thermal bonding technique

Effective filtration area: ≥0.6 ㎡/10"

Diameter: 69.0 mm

Max. operating temperature: 80℃,0.17 MPa

Max. bear temperature: 140℃,0.27 MPa

Max. forwarder differential pressure: 0.42 MPa(25℃)

Max. reverse differential pressure: 0.28 MPa(25℃)

Sterilizing temperature: 121℃ 30 min

Others: special requirement of diameter and end caps can be customized

Typical ApplicationsChemical industry: filtration for organic solvent, various alcohols, chemical reagent

Gas filtration: sterile filtration of compressed air, nitrogen, carbon dioxide Filtration for sterile tank respirator, air fermentation tank

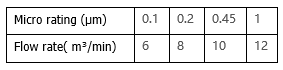

Pure water flow rate reference table: the initial value of 10"cartridge L/min (△P=0.01MPa, 1cP, 25℃)

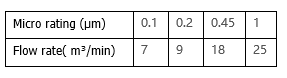

Air flow rate reference table: the initial value of 10" cartridge m³/min(△P=0.01MPa)