-

OD 131mm Series Filter Cartridge

IntroductionARLIT 131 series pleated filter cartridges are designed for large flow filtration to meet the new market requirements, mainly used for liquid filtration of production processes in electronic industry, liquid crystal display (LCD), chemical industry and food industry. It is suited for most LCD wet processing applications, such as substrate cleaning, etching, stripping and DI water flushing. Also applied in chemical and food industry which required large flow filtration. The filter membrane depends on your requirements, filter cage and core is made of polypropylene and produced by hot melt. Widely used for high flow filtration of liquid and gas. Provide a wide range of pore size from 0.1μm to 60μm. The effective filtration area from 1.2㎡ to 2.0㎡, with high flow rate, long service life, stable performance and wide chemical compatibility. It also can be used for liquid filtration of acids, alkali and solvent. Specifications and technical parametersFilter medium: PP membrane, PTFE membrane, PES membrane

Support layer: PP

Filter cage: PP

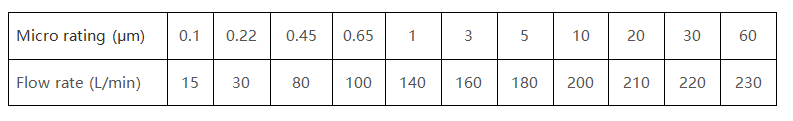

Pore size: 0.1、0.22、0.45、0.65、1、3、5、10、20、30、60 (um)

Length: 245mm, overall length 265mm

Gasket/O-rings: Silicone, NBR, EPDM, Viton

Sealing technique: thermal bonding

Effective filtration area: 1.2~2.0 ㎡/10”

Diameter: 131.0mm

Max. operating temperature: 80℃,0.28Mpa

Max. forwarder differential pressure: 0.42Mpa(25℃)

Max. reverse differential pressure: 0.28Mpa(25℃)

End caps: 334

Sterilizing temperature: 121℃ 30min

Others: special requirement can be customized

Typical ApplicationsElectronic industry: filtration for LCD wet process, semiconductor process, chemicals and pure water, organic solvent

Chemical industry: filtration for solvents, chemical reagent, ink

Food industry: filtration for beverage and wines

Others: filtration for photoresist, magnetic media

Pure water flow rate reference table: the initial value of 10"cartridge L/min (△P=0.01MPa, 1cP, 25℃)